POWERTRAX

Information and Manuals

Give our knowledgeable customer service staff a call today! Toll Free 1-800-934-2727.

The POWERTRAX LOCK-RIGHT Locker is the original locking differential that could be easily installed in existing case assemblies without any special tools or setup equipment. It has been widely used in demanding off-road applications around the world requiring extreme traction output and high-strength.

Because the LOCK-RIGHT eliminates wheel spin-up and therefore its associated driveline trauma is negated, the strength and integrity of its surrounding original case and other driveline components are, in effect, substantially increased. Cases that occasionally fail with open or limited-slip/posi differentials become one of the strongest links in the drive train when equipped with the POWERTRAX LOCK-RIGHT LOCKER.

The LOCK-RIGHT has been used in the harshest conditions around the world by hard-core off-roaders, in towing applications, and even United Nation vehicles in rugged terrain.

For traction output, strength and durability, the POWERTRAX LOCK-RIGHT Locker. rivals much more expensive competitive lockers sold only as complete case replacement assemblies. It is a leading product because the LOCK-RIGHT delivers as much traction output, its end assembly is exceptionally strong, is much less expensive, and does not require professional installation (because the complete case assembly does not have to be replaced and realigned with precision calibration equipment). An excellent choice for off-road vehicle applications, performance enthusiasts also began using the LOCK-RIGHT LOCKER to satisfy their extreme traction requirements for racing, hot-rods and muscle cars.

The LOCK-RIGHT’s operation is fully automatic. Designed to send the engine power to the wheels with the most traction, the LOCK-RIGHT will help get you where you want to go. While traveling straight the LOCK-RIGHT will lock the axles together similar to a spool. However, when the wheels need to differentiate in a turn, the LOCK-RIGHT will allow the outside wheel to rotate faster to complete the turn. The internal gears on the LOCK-RIGHT will overrun each other to allow this differentiation.

When operating off-road, the LOCK-RIGHT will always send the engine power to the wheels that need it most. For example, if you are rock crawling and one wheel is in the air (complete loss of traction), the wheel on the ground will receive the engine power and keep you going. Whether it be snow, sand, mud, ice, etc… the LOCK-RIGHT will give you the traction you need.

Although smoother than other competitive locking differentials, the brute force characteristics of the POWERTRAX LOCK-RIGHT Locker limit general application in less tolerant and more mainstream applications. In some vehicles, you will hear a light clicking noise as the gears are overrunning themselves and allowing the wheels to differentiate in a turn. This is normal of most lockers on the market today. We recommend the LOCK-RIGHT for vehicles that are primarily driven in severe driving conditions or are used for recreational off-road. For vehicles that are driven daily or require more mainstream application, the POWERTRAX TRACTION SYSTEMS offer a quieter and smoother performance. Please see the POWERTRAX® TRACTION SYSTEMS page.

Operation

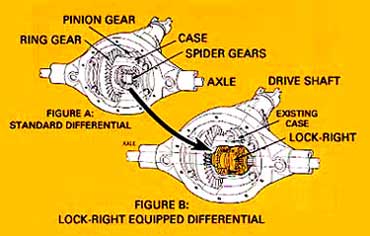

The POWERTRAX LOCK-RIGHT Locker is shown in the diagram (click to view full detail) and consists of two Drivers, two Couplers, and two Spacers. Most General Motors, Chevrolet, Jeep, Chrysler, Toyota, and late model Fords have this type of assembly. Many import vehicles that have four pinion differentials and the Ford 9-inch will differ slightly from the picture above.

The POWERTRAX LOCK-RIGHT Locker is shown in the diagram (click to view full detail) and consists of two Drivers, two Couplers, and two Spacers. Most General Motors, Chevrolet, Jeep, Chrysler, Toyota, and late model Fords have this type of assembly. Many import vehicles that have four pinion differentials and the Ford 9-inch will differ slightly from the picture above.

Power is transferred to the wheels through intermeshing teeth in such a way that one wheel cannot be powered ahead of the other. When entering a turn, where the outside wheel needs to travel faster than the inside wheel, the teeth driving the outside wheel disengage. The LOCK-RIGHT Locker is quieter than competing locking differentials, but nonetheless, as the vehicle continues through the turn, the teeth repeatedly engage and disengage producing a ratcheting sound.

The figure on the bottom of the diagram (click to view full detail) demonstrates the operation of the LOCK-RIGHT Locker. When powering straight ahead, the cross-shaft engages the saddles in the drivers at an angle such that, in addition to rotating the drivers, forces the teeth of the drivers into engagement with the teeth of the respective couplers. The harder the driving torque, the stronger the tooth engagement. When entering a turn, the driver on the outside of the turn advances ahead of the cross shaft so there is no torque or outward force imposed on this driver. The opposing driver remains fully engaged delivering engine power. After about 1° of rotation, the pins in the driver bottom out in the holes of the opposing driver, so it is now restrained from further rotation. Because the coupler is splined to the axle, it continues to rotate ahead of the driver. The positive angle on the coupler and driver teeth then enables the driver to disengage from the coupler with 1/2° of additional rotation. As the vehicle continues through the turn, the driver repeatedly engages and disengages from the coupler, making the aforementioned ratcheting sound. The springs between the two drivers ensure that the driver will reengage with the coupler when the vehicle exits the turn. The cross-shaft contacting the saddles provides the final engagement force, not the springs. In summary, the LOCK-RIGHT Locker offers full wheel differentiation combined with maximum traction.

Installation

LOCK-RIGHT is known for its ease of installation. In most applications, the complete installation takes less than two hours. No special tools or oils are required. Anyone with basic mechanical skills can install the LOCK-RIGHT with common tools (wrench, screwdriver). Detailed instructions are provided with each unit that include diagrams and photos.

There are basically two different types of installation.

1. Differential cases that you can access through the rear differential cover. Most AMC, Chrysler, Jeep, General Motors, and late model Ford vehicles have differentials that require this type of installation. This installation is the easiest because you simply remove the rear differential cover bolts to access the differential case. A summary of the steps are as follows:

* Remove the bolts on the differential cover and drain the oil.

* There is a cross shaft retaining bolt that holds the cross shaft in place. Remove this bolt and the cross shaft can be removed.

* Push in each axle to remove the c-clips (if the vehicle has c-clips). C-Clips hold the axles in place. On some vehicles, the axles are held in place at the outer ends of the axles near the wheels.

* Remove the stock side and spider gears and the thrust washers that are on the these gears.

* Install the Lock-Right gears in place of the original side and spider gears. The thrust washers are re-used. If the vehicle uses c-clips they are put back in place.

* Install the cross shaft, retaining bolt, differential cover and fill with oil.

2. A second type of installation involves a vehicle with a third member. Third member style differentials are removed from the driveshaft side of the vehicle (Ford 9 inch and most import vehicles). Installation in these types of differentials is easy once the third member is removed from the vehicle.

* Disconnect the driveshaft.

* Remove the third member from the differential carrier.

* Remove the side gears, spider gears, and the thrust washers that are on these gears.

* Install the Lock-Right gears in place of the original side and spider gears. The thrust washers are re-used. Install the cross shaft.

* Put the third member back in place and fill with oil.

NOTE: This is a brief description of the installation instructions and is not to be used for actual assembly. A detailed owners and installation manual come with every Lock-Right kit. Vehicles that have low gear ratio’s (numerically high) can often require a more extensive installation because of the ring gear thickness.

Application Guide

The LOCK-RIGHT Locker can be installed in a wide range of domestic and import vehicles. We currently have over 60 different models fitting over 100 different vehicle types.

We have made every attempt to verify that this application guide is as accurate as possible. If you have any further questions, don’t hesitate to contact us via phone or e-mail. The application listings are in Adobe Acrobat format.

Whether you have a truck, car, jeep or competition vehicle, odds are that we have a system for you!